Manufacturing & Operational Organizations

We Help Leaders Build High-Performance Operational Organizations

Manufacturing and Operational Organizations Rely on Precision, Consistency, and Coordination

Yet performance varies widely across shifts, supervisors, and sites.

,As organizations grow and adopt automation, teams begin to think, behave, and decide differently, creating performance drift that disrupts throughput, increases errors, slows communication, and impacts safety.

How LoyaltyOps Improves Performance In The Manufacturing Sector

Aligned Leadership Behavior, Team Execution, And Operational Delivery

LoyaltyOps helps manufacturing and operational companies through a structured installation that aligns behavior across executives, plant leaders, supervisors, and frontline teams. You'll ensure decisions, communication, and execution follow one consistent standard, creating more predictable throughput and safer, more reliable operations.

What We Strengthen:

Behavioral alignment across shifts, sites, and teams

Decision consistency under time-sensitive conditions

Supervisor accountability and expectations

Team execution rhythms and role clarity

Cross-functional communication across operations, maintenance, and quality

Client and operational reliability

Strengthen Performance In Your Manufacturing & Operational Organization

LoyaltyOps™ Aligns Leadership, Stabilizes Execution, And Improves Reliability Across Plants, Shifts, And Teams

Schedule a discovery call to explore we help strengthen leadership behavior, improve team performance, and make execution consistent across shifts, roles, sites, and operational functions.

The ROI Of Performance Alignment In The Manufacturing Sector

Consistent Behavior Creates Reliable Execution — Which Drives Measurable Results

Reduce friction, stabilize execution, and protect profitability in high-volume, high-pressure manufacturing environments.

Lower downtime and operational delays

Reduced rework, scrap, and error rates

Clearer decisions and faster problem resolution

Better alignment across shifts, sites, and functions

Fewer escalations and bottlenecks

Improved safety and compliance performance

Stronger margins and more stable throughput

Higher confidence in operational performance

What Makes LoyaltyOps Different In The Manufacturing Sector

A Systemic Approach Competitors Don’t Offer

Most manufacturing solutions focus on Lean tools, process optimization, equipment, or training programs. LoyaltyOps™ aligns leaders, supervisors, and frontline teams, something no traditional operational consulting firm provides.

Traditional Operating Frameworks

They define process but not behavior.

You need to align how people think, behave, and decide, making processes actually work.

HR, Surveys, And Engagement Platforms

They measure sentiment, not execution.

You need to correct the behavior patterns causing drift and inconsistency.

Consulting Firms & Advisors

They provide insight, not lasting discipline.

You need a system teams follow daily, across shifts and sites.

Offsites, Training, And Team Building

They diagnose problems but do not change how teams behave on the line.

You need to transform behavior and execution, not just recommending improvements.

This is why manufacturing and operational organizations choose LoyaltyOps™ when reliable execution and scalable performance matter.

Results Manufacturing & Operational Organizations Achieve With LoyaltyOps™

When Behavior Aligns, Performance Improves Consistently And Measurably

Operational organizations see immediate improvements when leaders and supervisors model standards consistently and teams follow aligned behavioral expectations.

Throughput increases, errors decrease, communication strengthens, and shifts operate with more reliability and fewer disruptions.

Start With a Conversation

3 Easy Steps To Get Started

1. Book a

Discovery Calll

Start with a conversation to understand where performance is breaking down today, and whether LoyaltyOps is the right fit.

2. Build a Team That Wins

Leaders work through a structured process to define clear standards and design the environment that makes high performance the default.

3. Win Again and Again

Teams operate with confidence and momentum. Decisions move forward, commitments hold, and winning becomes repeatable as the business grows.

Ready to get started?

Recommended Insights

Resources to Support Manufacturing & Operational Organizations

From Chaos to Consistency: The Discipline Behind High-Performing Teams

High-performing teams are built through disciplined leadership, cultural clarity, and aligned systems. Learn how to move from chaos to consistency inside growing organizations. ...more

Leadership & Behaviour

February 19, 2026•6 min read

How Overfunctioning Becomes a Career Trap for Women Entrepreneurs and CEOs

Overfunctioning often looks like leadership but creates bottlenecks and burnout. Learn how women CEOs replace overextension with clarity and disciplined execution. ...more

People — Leadership, Culture & Behaviour

February 19, 2026•4 min read

The Hidden Cost of Lack of Clarity at Work for High-Performing Women

High-performing women often burn out in unclear systems. Learn how ambiguity drives overfunctioning, hurts confidence, and how leaders can restore clarity. ...more

People — Leadership, Culture & Behaviour

February 19, 2026•5 min read

Contact Us

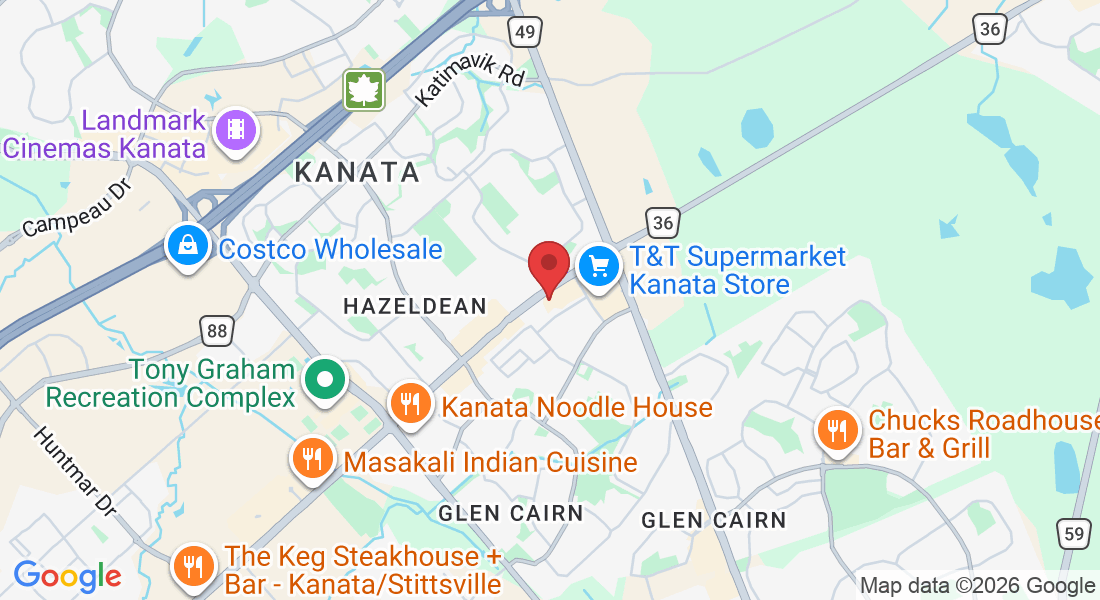

LoyaltyOps™ HQ

430 Hazeldean Road,

Unit #6, Suite 17

Kanata, Ontario, Canada

K2L 1T9

Email: [email protected]

Phone: 1 365-659-4720

Facebook

LinkedIn